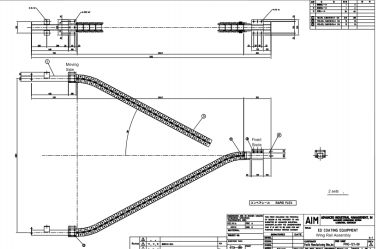

WING RAIL is a flexible roller conveyor chain rail.The hunger jig traverser and crush accidents in it can beeliminated by this flexible roller chain rails in indexing E-Coat line!

Feature- Applicable to standard over head chain conveyor. RAPID & TSUBAKI trolley conveyor.I Beam or Enclosed Track.(Heat-resistant specs)

- Eliminate traversers from Square Transfer type E-coat Systems. Reduce cost for Conveyor.Simplify the control. Relieve Customer from traverse accident.

- Capacity.Load Capacity Min. 22lb(10kg) ~ Max. 2,200lb. (1,000kg)/hanger

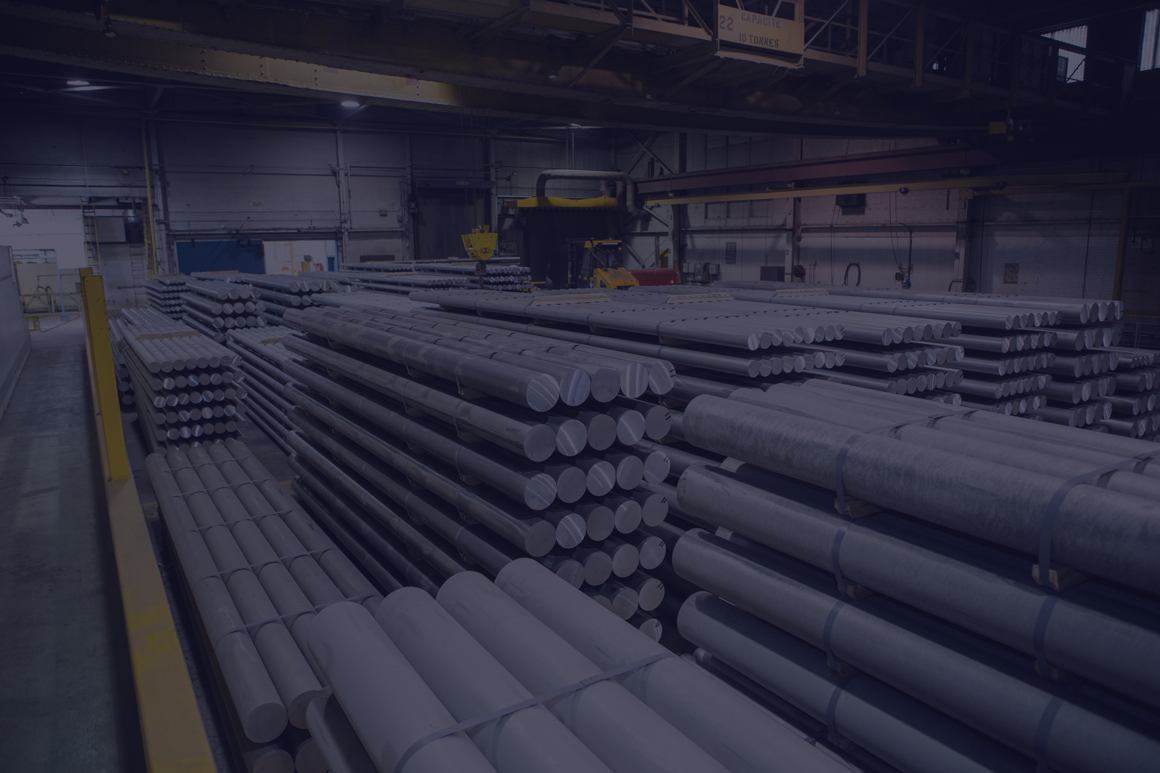

Full Turnkey Anodising/Passivation for Aerospace industry

Automatic Spray Paint System

AIM can help localizing Large Paint system by managing from bidding to Installation.

RELOCATION

Anodizing Line

Disassemble , Transportation , and Installation.Including Waste Water Treatment System.Upgrade Cleaning Capability

Mixing Machine

Disassemble , Transportation , and Installation.Design and Build Mezzanine.

REFURBISH/ MODIFICAION

E-Coat Line

Disassemble and Transportation, and Installation.

AIM refurbished Used E-Coat Line stored in warehouse for 5 years.

Rebuild and Improvement of Zink Plating System

With a tight schedule, AIM managed to overhaul and improve existing design with great efficiency. New design has been an improvement over existing and greatly improved customer's down time.

AIM measured existing machines, redesign and manufactured new transfer unit since original maker closed their business and no detail drawing for it.

Engineering Corroboration with Japanese Maker

To transfer Japanese high technology to US, AIM corroborated with Japanese maker of Surface Treatment Systems.Key technology designed in Japan had been built into the drawing and Manufactured by AIM. Nearly all part of system could be localized.

Full automatic Barrel Zinc Plating line

Full Automatic Anodizing Line