Equipment Systems Installation, Modification and Relocation. When Budget, schedule and safety are your main concern, AIM will help you DO-IT-RIGHT the first time.

RELOCATION / MOVING

STAMPING INSTALLATION

Large Stamping Presses installation

Including Design Pit, pit covers, safety fences, misc.CASTING INSTALLATION

2250 ton / 800 ton / 500 ton Die cast equipment:

Retractable Die cast hood for mist collection system

Melting Furnace Exhaust

System

Billet Casting System / Homogenized Furnace

Install total system with engineering exhaust system.

Including induction melting furnace, Casting system, 3 stage Homogenized Furnace.Designed and built Hume collection system and Automatic Furnace hot exhaust station switching Control systems.

Large Mist Collection Removable Hoods for the Casting Industry

Billet Casting System / Homogenized Furnace

Install total system with engineering exhaust system.

Including induction melting furnace, Casting system, 3 stage Homogenized Furnace. Designed and built Hume collection system and Automatic Furnace hot exhaust station switching Control systems. Lorem ipsum dolor sit amet, consectetur adipiscing elit, sed do eiusmod tempor incididunt ut labore et dolore magna aliqua. Ut enim ad minim veniam, quis nostrud exercitation ullamco laboris nisi ut aliquip ex ea commodo consequat.

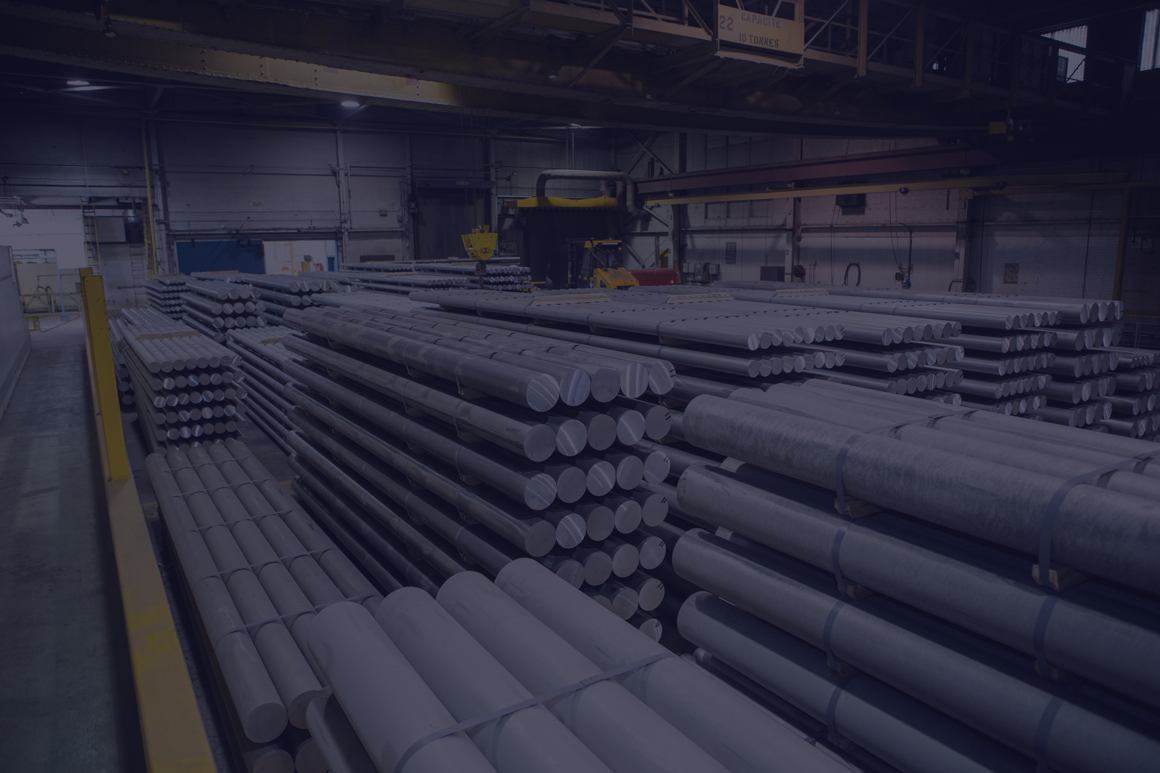

ALUMINUM INSTALLATION

3,000Ton Extrusion Press System

Including Over Head Crane, Material Preheating system, Cooling Conveyor system.

Machining/Welding/Assembly Line Installation

Machining Lines

Including specialty items design fabrication Complete welding lines installation, including engineering & fabrication items such as safety gard and fume collecting system.